| Web

and Book design,

Copyright, Kellscraft Studio 1999-2008 (Return to Web Text-ures) |

(HOME)

|

|

CHAPTER XIV OTHER CRAFTS AND CRAFTSMEN BEFORE closing this volume it may not be un interesting to take a passing glance at some of the minor crafts and craftsmen that form a part of the early history of industrial arts in America. Two chapters have already been devoted to clock-making, but the Willards and the Connecticut group were not the only clockmakers worthy of consideration, though they were the most important. Clockmakers came here from England and Holland early in the seventeenth century, but little is known of them or of their work. The names of most of the clockmakers of the first half of the eighteenth century are also missing. Clockmakers did not commonly sign their work until later; the practice of pasting a paper of directions inside the case did not become general until about 1800. Many an interesting old clock is owned to-day about which practically nothing is known as to history or maker. One of the earliest names on record is that of William Davis, who was making clocks in Boston in 1683. James Batterson was at work and advertised there between 1707 and 1730 and Thomas Bodeley in 1720. The clocks of these early makers are very rare, and offer but little opportunity for the collector. The most prominent name found among the Boston clockmakers of the first half of the eighteenth century is Bagnall. Benjamin Bagnall made tall, eight-day clocks in Charlestown, in pine and walnut cases, as early as 1712. He was succeeded in 1740 by his sons Samuel and Benjamin, Jr., who did business in Boston. The latter had a shop on Cornhill, near the Town House, in 1770. During the last quarter of the century there were many successful clockmakers in Boston, including Joseph and Robert Pope, D. F. Lanny, Richard Cranch, and others. Early clockmaking was also carried on in Plymouth and in other towns of eastern Massachusetts. Newbury was something of a center for the industry. Here Balch and Mulliken were prominent names. Samuel Mulliken was born in Bradford, Massachusetts, in 1720 and moved to Newbury in 1750, where he made clocks for about six years. He was succeeded by his son Jonathan and by his grandson Samuel, who made clocks in Newburyport until about 1790. There was also a Joseph Mulliken who died in Newburyport in 1804, a Nathaniel Mulliken who lived in Lexington from 1751 to 1789, and another Samuel Mulliken who advertised clocks in Salem in 1789. Daniel Balch was born in Bradford in 1734 and moved to Newbury in 1757, where he made clocks for thirty years. He was succeeded by his sons Daniel and Thomas. Thomas kept up the business till 1818, making excellent clocks, and was then succeeded by his son Charles. There were also Benjamin and James Balch in Salem in 1787. Another well known Newburyport clockmaker was David Wood (1766-1824). At

a somewhat later date the name of Munroe be came famous in Concord,

Massachusetts. Here Daniel and Nathaniel Munroe, brothers, made

clocks from about 1800. ln 1808 Daniel moved to Boston and Nathaniel

continued the business with Samuel Whiting until 1817, when he moved

to Baltimore. They did a large business in eight-day clocks with

brass works. Nathaniel also had a brass foundry where he made bells,

clock works, etc.

I have already made reference to Lemuel Curtis, and to Elnathan Taber and Simon Willard's other apprentices. (See Chapter VI.) In Rhode Island the Claggetts were famous clock. makers in the first half of the eighteenth century, and a few examples of their work are still to be seen. Between 1726 and 1740 H. Claggett was making tall clocks of superior quality in Newport. Thomas and William Claggett, presumably his sons, were engaged in the business between 1730 and 1750. ln 1788 Seril Dodge, who was a gold- and silver-smith as well as a clockmaker, was at work in Providence. From 1794 to 1824 Nehemiah Dodge was engaged in these two trades, being succeeded by Ezra W. Dodge, probably his son. Other Providence clockmakers were Caleb and Calvin Wheaton, about 1784 to 1790. The Connecticut clockmakers, beginning with Thomas Harland in 1773, have already been considered. (See Chapter V.) In Philadelphia one of the earliest known clock makers was Christopher Sower. He was born in Germany in 1693, came to Philadelphia in 1724, and engaged in the clock-making trade in German town in 1731, when we find his name spelled Souers. He made tall eight-day clocks of good quality. Be sides being a clockmaker, he was a physician, chemist, farmer, paper maker, book printer, and author. He also invented a cast-iron stove. Another early member of the craft in Philadelphia was Odran Dupuy, who was making clocks in 1735. John Dupuy, Who was in the business in 1770, was probably his son. Augustine Neiser was a Moravian who settled in Germantown in 1739 and made clocks until 1780. Most of these were signed with his name, but without date. Edward Duffield, a friend of Benjamin Franklin, was born in Philadelphia in 1720 and made clocks and watches there between 1741 and 1747. William Godfrey was another Philadelphia clockmaker between 1750 and 1763. The genius among the Philadelphia clockmakers was David Rittenhouse, who was born in German town in 1732, established his trade in Norriton in 1751, and moved to Philadelphia in 1770, where he made clocks until about 1777. He was a famous astronomer and constructed a remarkable astronomical clock which is now in Memorial Hall, Philadelphia. He was treasurer of Pennsylvania from 1777 to 1789, Professor of Astronomy at the University of Pennsylvania from 1779 to 1782, and Director of the United States Mint from 1792 to 1795. After the Revolution clockmakers were more numerous in Philadelphia. The directory of 1785 gives the names of nineteen and that of 1795 twenty-five. In New York imported clocks were largely advertised during the first half of the eighteenth century, but there were also a number of local clockmakers. Among the earliest on record was Everardus Bogardus, who was at work as early as 1698. John Bell advertised eight-day clocks in Japan cases in 1734. Long-case clocks with brass works were advertised by George Nicholls between 1728 and 1750 and by Lawrence Payne between 1732 and 1755. Thomas Perry was making clocks in Dock Street and Moses Clements in Broadway in 1749. Other pre-Revolutionary clockmakers in New York were George Chester and Carden Proctor, who were at work in 1757, John Ent and Patrick Carryl in 1758, and Joseph Clark in 1768. After the Revolution there were many more. In other cities the industry also thrived. Robert Shearman made clocks in Wilmington, Delaware, be tween 1760 and 1770. In Baltimore, where the trade flourished after the Revolution, Alexander Vuille was at work in 1766. The most complete list of early American clockmakers appears in Mrs. Moore's "Old Clock Book." LOOKING-GLASSES

AND FRAMES

While most of the so-called Colonial looking-glasses in America were imported, the making of mirror frames became a fairly profitable industry after the Revolution. The Queen Anne and Georgian types nearly all came from England. During

the last half of the eighteenth century a looking-glass became

popular in America which was a revival of the Queen Anne style. It

had a flat frame of solid or veneered mahogany, deeply curved at the

bottom and with the broken arch or some similar form at the top. The

frame was embellished with gilt ornaments, the eagle becoming popular

about 1775. There was often a molding around the inside of the frame,

and the glass, unlike its Queen Anne prototype, was squared.

By 1775 looking-glasses were manufactured in considerable quantities in New England, though still, apparently, imported in New York. Between 1780 and 1790 the so-called Constitution mirror was in vogue. It was similar in style to the one just described, with gilt plaster ornaments mounted on wires at the sides and with a gilt eagle of carved wood or plaster in the broken arch at the top. The gilt plaster eagle in bas relief occasionally found on the flat wood above the glass belongs to a later period — about 1810. Toward the close of the century gilt-framed glasses of various types were made here. One of the finest of these was the circular bull's-eye mirror, with convex glass and with an ornate gilt frame of carved wood or molded plaster or a combination of the two. It was ornamented with heavy beading or rows of balls and frequently had a spread eagle at the top. These bull's-eyes varied from twelve to thirty-six inches in diameter, the smaller ones being frequently used in pairs. Some, called girandole mirrors, were furnished with two or more candle holders. They were made between 1780 and 1800. Over-mantel glasses of various sorts were common after 1780. They were made chiefly with three sections of glass, separated by molding, the two end sections being narrower than the middle one. After 1800 heavier pilasters divided the sections. Similar looking-glasses were made in upright form with two sections of glass, the smaller section at the top often being ornamented with a pattern cut out of wood and laid over it. After 1800 this upper section was more commonly painted with a crude landscape or emblematic design. After 1805 Empire styles began to come into vogue. Between 1810 and 1830 the commonest form of looking-glass had a heavy gilt frame, often with an overhanging cornice at the top ornamented with pendant balls or acorns, the rest of the frame being rounded, spiral, or fluted. After 1825 heavy balluster forms appeared on all four sides. Little has been recorded of the men who made these looking-glasses. James Foddy advertised in New York in 1730 "to alter and amend old looking-glasses." George Robinson, a Boston carver, who died in 1737, is known to have made frames, and William Farris was a carver and gilder of looking-glass frames in Baltimore in 1796. Few of their names are known, however, and it is probable that most of them were among those listed as carvers in the old directories. GLASS-MAKERS

Baron Stiegel, though the most interesting of the early American manufacturers of glassware, was not the first. Window glass and bottles were manufactured in Jamestown, Virginia, as early as 1609, and another factory started there in 1621 made glass beads for barter with the Indians. Salem had a glass-house in 1639, where coarse bottles were made. Glassware was also made in Philadelphia by Joshua Tittery in 1683 and perhaps in other places, though these seventeenth century ventures were not generally successful. In 1739 glass works were established at Allowaystown, later Wistarburg, Salem County, New Jersey, by Caspar Wistar, and were continued by his son Richard until 1781. Here window glass and bottles of good quality were made, as well as a few beautiful specimens of higher grade glassware showing Dutch characteristics. There were two factories in New York as early as 1731, one in Connecticut in 1741, and one in Brooklyn in 1754. Crude bottles were made at Quincy, Massachusetts, in 1760. Bottles and flasks were made in Kensington, Pennsylvania, about 1771, and in 1775 Stanger Bros. started a factory at Glassboro, New Jersey. Robert Hewes of Boston started a glass-house at Temple, New Hampshire, in 1779, but it was not a success. After the Revolution other glass factories were started in Philadelphia, Pittsburg, Baltimore, New York, Albany, New Jersey, and New England. In 1783 William and Elisha Pitkin and Samuel Bishop Were given the sole privilege of making glass in Connecticut. The Pitkin factory was located at East Hartford.

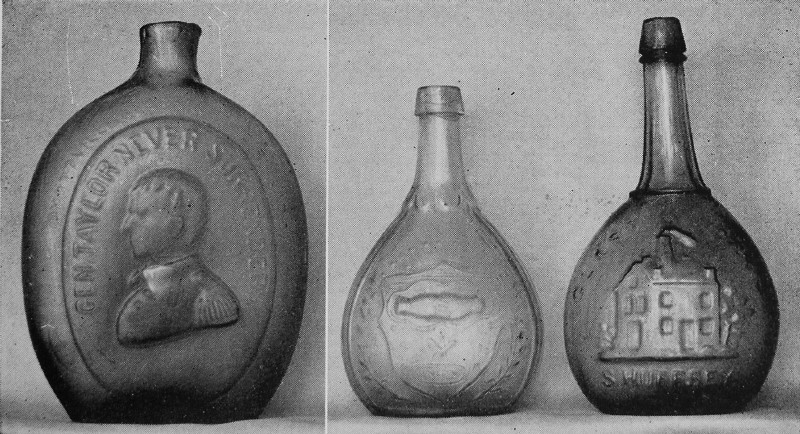

The first American glass was greenish, coarse, and full of bubbles and sand. After the Revolution the quality of the material was improved as well as the designs. Salt cellars, bowls, pitchers, bottles, and all sorts of drinking glasses Were made in pressed and cut glass, up to about 1810. These were followed by blown glass up to about 1827, when the modern industry was established. American drinking glasses form an interesting field for the collector, and there are various sorts of ornamental and table ware and lamps. In some respects, however, the bottles form the most alluring field. The need for bottles and flasks was felt as early as the seventeenth century, but the first ones made here were coarse and crude and in the simplest forms. Later, blue and brown glass appeared in place of the light and dark green, and more attention was paid to the matter of shape. After the Revolution bottles began to be made with some form of decoration. As early as 1790 bottles bearing the heads and busts of noted men were made in Baltimore. After 1800 curious shapes began to appear — men, animals, fishes, shells, books, violins, and pistols. About 1810 bottles were made in the form of crude busts of Washington and Lafayette. The vogue for fancy bottles and pocket flasks, bearing blown decorations of political or historical significance, lasted from 1808, when they began to appear in Philadelphia, till about 1870. They were made in various colors, which do not serve as an indication of their date of manufacture. The designs were cut in metal molds. of the eighty or more patterns that have been found, twenty-nine show the American eagle, nineteen are of Washington, and nineteen of General Zachary Taylor. The popularity of these bottles was in full swing by 1825, when several factories made flasks and bottles to commemorate the opening of the Erie Canal. These included busts of Lafayette and Governor Clinton. The presidential campaign of 1840 was made the occasion for the manufacture of a large number of bottles in the form of campaign emblems, such as the log cabin, the beehive, and the cider barrel. The idea caught the popular fancy and souvenir bottles were much in demand during the next fifteen years. The Mexican War furnished another subject and in 1848 General Taylor and Captain Bragg bottles were popular. In 1850 flasks with globular bodies and long necks were dedicated to Jenny Lind and Louis Kossuth and bore their names and likenesses. Other popular subjects were Henry Clay, Robert Fulton, and Thomas Jefferson. Not

a great deal is known of the makers of these bottles. Campaign

bottles of 1840 and Mexican War bottles were made at the Kensington

works, which were started by Robert Towars and James Leacock in 1771,

and were taken Over by Thomas Leiper in 1783 and by James Rowland &

Co. in 1813. The factory at Glassboro, New Jersey, which was started

by Stanger Bros. in 1775, passed into the hands of Whitney Bros. in

1840. They made whiskey bottles and also ink-stands in the log cabin,

cider barrel, and beehive forms, and, in 1750, Jenny Lind bottles.

Samuel Huffsey of Philadelphia also made Kossuth and Lind bottles,

often using the mark S. Huffsey.

These bottles make an interesting if not an especially beautiful or antique collection. The largest number were made between 1848 and 1852, and practically none now in existence were made before 1825. They are worth from $1 to $10 apiece, according to age and rarity of design. The same is true of the cup-plates — the little glass dishes that grandfather used to set his cup on while cooling his tea in his saucer. These were also especially popular between 1840 and 1850, and bore the campaign emblems, state coat-of-arms, and such historical scenes as the Battle of Bunker Hill. These cup plates are worth from 25 cents to $5 apiece, $1 being a fair average value. The opal glass which was in vogue about 1820 is also interesting. It is found in lamps, candlesticks, door knobs, curtain and drawer knobs, and various small articles. IRON

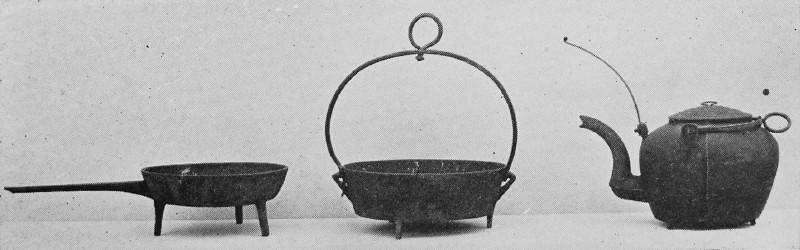

FURNACES

The history of iron casting in America I shall not attempt to treat as fully as so important an industry deserves, for the reason that it cannot have so great an interest for collectors as some of the others. ln 1630 Thomas Hudson settled at Lynn, Massachusetts, on land near the ford of the Saugus River. His discovery of bog-iron ore in his marsh led to the establishment of the first iron foundry by Joseph Jenks. Charcoal was the fuel used, and the first casting done in America was an iron pot made in 1642. In 1652 Jenks cast the dies for the famous pine-tree shillings. In 1646 there was also a foundry at Braintree, Massachusetts, where pots, mortars, stoves, and skillets were made. During the eighteenth century Pennsylvania be came the center of the iron industry and furnaces were also established in Maryland, New Jersey, and elsewhere. Among the products manufactured in Pennsylvania were the five-plate and six-plate stoves which were built into the jambs of fireplaces. They had no connection with the flue and were open on the side toward the fire. Hot coals were shoveled into them, and the heated iron, extending into the room, radiated a fair degree of warmth. The side and end plates of these stoves were cast in raised designs, and it is these quaintly decorative stove-plates that are of chief interest to the collector. The Metropolitan and Pennsylvania Museums own a number of them, and Mr. Henry C. Mercer of Doylestown, Pennsylvania, has made a particular study of them, as well as of Moravian tiles and Pennsylvania-German pottery. Another collector of stove-plates is Mr. Benjamin F. Owen of Reading, Pennsylvania. These plates are from one and one-half to two and one-half feet square, and often half an inch thick or more. The tulip was a common design motif, and many of the plates bore inscriptions in German. The most interesting subjects illustrate scriptural incidents, such as the stories of Cain and Abel, Adam and Eve, David and Goliath, Joseph and Potiphar's wife, the Miracle of Cana, the flight into Egypt, and Elijah and the ravens. Among the known makers of these stove plates were Thomas Rutter, the Durham Furnace in Bucks County, Daniel Udree at Oley in Berks County, John Potts at the Warwick Furnace in Chester County, and Baron Stiegel at Elizabeth Furnace in Lancaster County. They date from 1735 to 1790, but the best examples were made between 1740 and 1760. With the introduction of the ten-plate stove the decorations became less interesting. Daniel Udree is said to have burned 840 bushels of charcoal in his furnace every twenty-four hours, and it took twenty-two cords of wood to make that much charcoal. Naturally, wood began to be less plentiful and more expensive in the region of Philadelphia, and this led to the invention of the Philadelphia fireplace to economize fuel. This was improved by Benjamin Franklin, and Franklin stoves began to be made about 1745. Franklin had made a study of fireplaces, chimneys, and draughts, among his many other scientific investigations, and his own account of his invention is interesting. In his autobiography he writes as follows: "Having, in 1742, invented an open stove for the better warming of rooms, and at the same time saving fuel, as the fresh air admitted was warmed in entering, I made a present of the model to Mr. Robert Grace, one of my early friends, who, having an iron-furnace, found the casting of the plates for these stoves a profitable thing, as they were growing in demand. . . . The use of these fireplaces in very many houses, both here in Pennsylvania and the neighboring states, has been, and is, a great saving of wood to the inhabitants." The Franklin stoves were built of cast iron, to be fitted into the fireplace, or to extend out into the room, with a flue connection. Some were very simple in arrangement, while others had more or less elaborate systems of draughts. The old fireplaces were not always smokeless, and the new stove was an improvement in that respect. Sea coal was advertised in Philadelphia as early as 1744, and Franklin stoves were soon made with grates as well as with flat hearths for andirons. The designs were often good, the jambs curving gracefully and the proportions pleasing. They were decorated with embossed patterns in the iron and with brass or nickel knobs and sometimes rosettes and rails. They were made with and without feet. It is not impossible to find old Franklin stoves occasionally to-day, though care should be taken not to be deceived by the modern reproductions which soon get to looking old with use. The ordinary types are worth $15 or $20. Among the other interesting products of the old furnaces were decorative firebacks for fireplaces, andirons, door knockers, and building hardware. Old architectural wrought iron, such as is to be found in Charleston and elsewhere, is a subject for study by itself. THE

TEXTILE ARTS

We

have been dealing, of course, with the work of professional

craftsmen, while some of the interesting art objects of the

seventeenth and eighteenth centuries were the work of amateurs. The

textile arts especially — needlework and weaving — should be

classed as home crafts. An American hand-woven coverlet of the late eighteenth century. From the Metropolitan Museum Collection Lace, tapestries, silks, the finer floor coverings, and other textiles were largely imported until well into the nineteenth century, but the homespun work was not always lacking in artistic interest. As early as the beginning of the eighteenth century there were professional weavers, who, like the itinerant cobblers, went from farmhouse to farmhouse, carrying their looms with them and doing the year's stint of work. It was doubtless from these weavers that the Colonial housewives learned to improve the character of their own weaving, for this remained for generations part of women's work. For

the collector there is perhaps nothing more interesting in this field

than the hand-woven cover lets which were made in every section of

the country from New Hampshire to Georgia. The art, indeed, still

survives in the Southern Appalachian Mountains. These coverlets were

quaintly beautiful, and as they were often carefully preserved, not a

few of them are still in existence. Some patterns were imported from

European countries by the early immigrants, and many were common to

all parts of the Colonies. They were often named. Miss Hall, in her

book on coverlets, has gathered a large number of these names and

designs. The colors were chiefly red and white or blue and white, but

green, pink, yellow, and saffron were also used. The vegetable dyes

were all home-made — an art that has been all but forgotten in this

country.

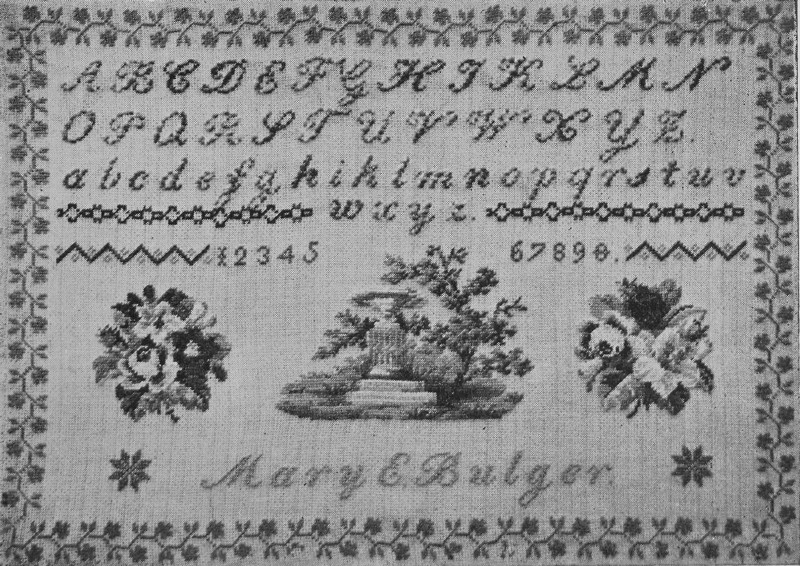

Needlework was always considered one of the accomplishments of the gentlewoman. She made "Turkey work," hooked and braided rugs, samplers, embroidered curtains and fire screens, etc. Embroidery, indeed, became one of the most widely practised of the fine arts. The teaching of needlework was a thriving industry in itself. In New York we find Martha Gazley advertising in 1731 to teach needlework, and similar advertisements were common after 1750. In 1769 Clementina and Jane Ferguson conducted a famous young ladies' finishing school in which needlework was one of the principal subjects taught. In Boston Mrs. Hiller had a similar school in Hanover Square and they were quite common during the '60's. There is, I think, nothing in the line of needle work so interesting to the collector as samplers. They are not uncommon, though they vary widely in excellence and in human interest. The oldest ones were the work of skilled needlewomen; samplers which were the tasks of little girls belong generally to some date after 1725. The history of weaving, printing, and the other industrial arts in America are all deserving of attention, but we have covered, I think, the subjects that are of the greatest present interest to collectors. This history, indeed, dull enough at first glance, soon becomes a part of the collector's treasured lore, and the collector of Americana is bound to become something of a historian. It

is my hope that I may have succeeded through this volume in turning

the attention of some few Americans to the collecting of Americana,

and I shall be still further gratified if the recently awakened

popular interest in this field may cause the directors of more of our

public museums to follow the lead of those in New York, Boston, and

Philadelphia and take steps toward the acquisition of comprehensive

collections of the work of our early American craftsmen. |