|

|

||

| Kellscraft

Studio Home Page |

Wallpaper

Images for your Computer |

Nekrassoff Informational Pages |

Web

Text-ures© Free Books on-line |

|

We

Discover some Innovative Features for the 1920s

One of the fascinating aspects of buying an old house can be determining what is original and what would be later upgrades and additions. For us, the outlets and baseboard fixtures told us a lot about the history of the House. 1. Knob-and-tube and Socket ‘Plugs” Yes, much of the wiring is still original to the 1920 date of the house. That means knob-and-tube. We know of two electical outlets original to the house and, yes, we discovered they still work! (Not a feature we exploit however. Knob-and-tube wiring and 1920s screw-in electrical outlets were not designed for the present current load from modern appliances so we avoid using these at all.) cover plate to 1920’s socket plug Trumbull (Electical Manufacturing Co.) socket (660 W. 250 V.)  Socket plug used to convert a bulb socket to an electrical outlet Obviously, the Trumblull socket outlet installed in the baseboard of the house must have been put in with a socket plug converter from the beginning. No one would expect to find a light bulb sticking out of a baseboard so close to the floor. Clearly, the floor plug in this House was an innovation for the time, allowing a dedicated line for appliances. Remember the single light bulb fixture hanging from the ceiling in the late Victorian, or turn-of-the-last-century house? That single light socket was quickly adapted to become socket outlets as new, wired appliances came into vogue. Got a new-fangled toaster or flat iron? Just insert a socket plug into the light socket and voila!, instant electrical outlet. Single sockets with multiple plugs meant even more items could be plugged in at the same time on one line. Remember A Christmas Story, when the father was plugging in the christmas tree lights and blew a fuse that knocked out the entire house? That was a common occurance. No, this was a deliberate innovation using the technology of the time. There was a conscious decision to have baseboard electical outlets in the house for new appliances.

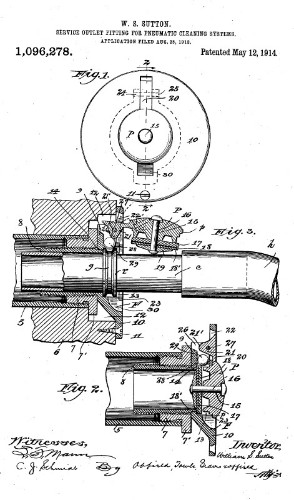

Yup, this house was fully ‘modernized’ for 1920, and running through the baseboards, walls and floors are piping and vacuum outlets to allow for convenient cleaning from floor to floor without lugging a heavy vacuum up and down stairs. Closed central vac cover in the baseboard on the upstairs landing  Design patented May 12, 1914, Pat# 1096278  Original Patent Application design for Service Outlet fitting for Pneumatic Cleaning Systems, 1914 (Click image to open full size image of the Patent) Remember that

when our house was built in 1920, its original intention

was as a guest house for visiting board members of the Maine Spinning

Company, the factory for which was located only a few hundred yards

away on

“the Island” in Skowhegan. Open central vac outlet “Stewart” logo on the inside of the central vac cover. Since the House was originally planned to be used infrequently, there were no rooms for full-time staff, and cleaners would only occasionally be expected in the House. To make their work quicker and easier, all the cleaners would need to do would be to carry the light cleaning hoses and wands up and down the stairs. Small closet where the central vac unit was located on the second floor Open closet showing where the capped vacuum pipes are still located and small opening in the ceiling where the vacuum vented to the outdoors through the roof. It may be one of the last ‘luxury” uprades we do in the House, but we’ll definitely be restoring this to a functioning system before we are done! Luckily, like light bulb sockets. vacuum hose connections were standardized early!

3. The 6-foot dumb waiter in the cellar…. When we first looked over the House, there was a mystery room in the cellar. The dirt and wood slat floor here was completely out of place with the poured concrete floor in the rest of the cellar. Door to the mystery room in the cellar… Note the rounded brick arch under the wood door frame Other than a

bath room, this is the only room in an otherwise open

cellar design. Around three quarters of the room are tiered shelves and

walled

in bins with dirt floors on the bottom. And in the corner, what we took

to be a

built-in cabinet. We’re not sure, but we believe this is the remains of

a root

cellar from the original construction (how we would love to find

Muzzy’s

architecural plans!) Shelving and bins underneath… remains of a root cellar? Hatch in the Dining Room floor…. That built-in

cabinet in the corner? Turns out it wasn’t as “built-in” as

we thought. When we pulled up the old wall-to-wall carpeting in the

dining

room, we found what looked like a hatch cut into one corner of the

room. It was

only then that 2+2 came together and we realized we had an access into

the

cellar from the dining room. And what was below the dining room? The

mystery

room. What was below the hatch? The “built-in” cabinet! Shelving and “built-in” cabinet Close up of the cabinet Pulley and motor system We started taking a closer look at that cabinet. Made of pine, we noticed the cabinet was actually built within an exterior frame, and when the door was closed, the entire cabinet sat inside the framing. Next we noticed the rope. Sticking up from the bottom of the frame was a broken white cotton rope, apparently leading to nowhere. And then, on the left side of the framing, just under the cellar ceiling, there was a small motor. It all started to make sense. Load up the shelves with items from the cellar (winter veggies, canned goods, even dishes?), close the door and start the motor. The rope, slung under the cabinet and up to the motor would start inching the entire cabinet up into the dining room! Once fully exposed in the dining room, a servant could unload its contents and send it back down into the cellar. No shlepping up and down the stairs from cellar to kitchen; this modern devise helped as a labor-saving device to do basic chores. This didn’t have to be done, but we are finding the Maine Spinning Co. owners were progressive with their staff as well as their mill workers (The Maine Spinning Mill was the first mill in Skowhegan to have an elevator installed for workers to move up and down the four-story building, and worker bathrooms on each floor. More to come on that later….) So, there you have it. More evidence of the unique qualities of this House! Next time: Ten Years On: We Look at the Importance of the House |