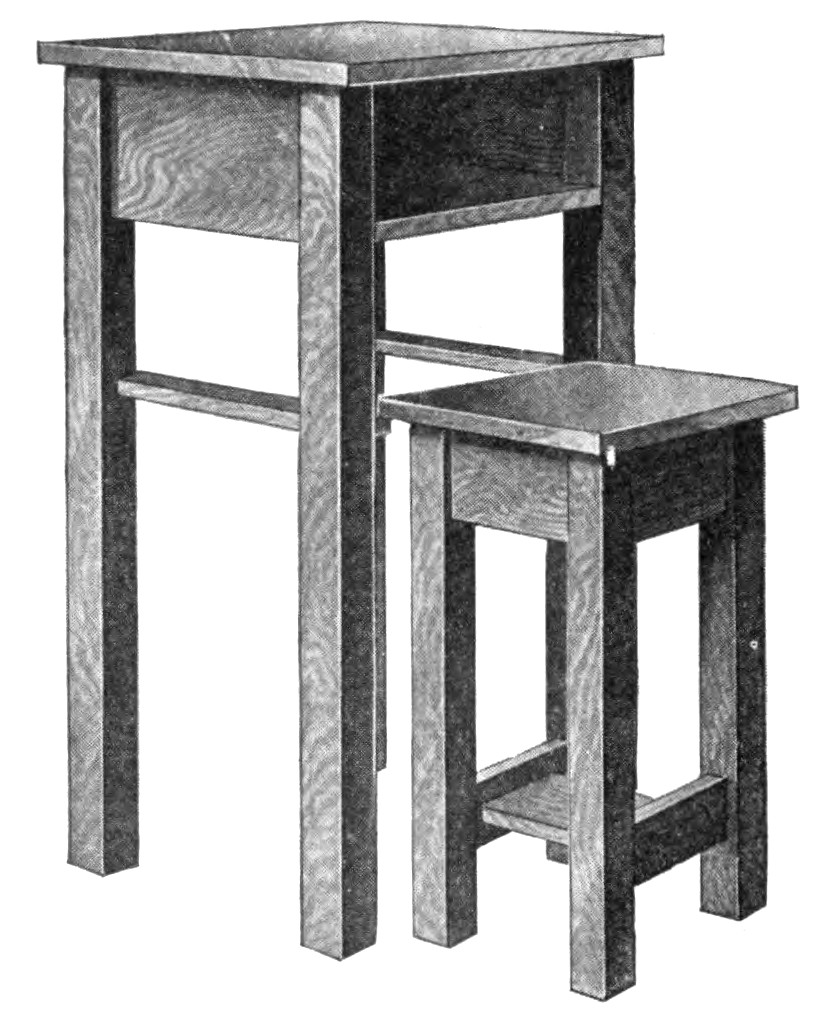

| A TELEPHONE STAND AND STOOL

The stand shown

in the

accompanying illustration is for use with a desk telephone. The stool

when not in use, slides on two runners under the stand.

Stand

and Stool Complete

A shelf is provided

for

the telephone directory, paper, pencil, etc.

The joints may

be made

with dowels, or the mortise and tenon may be used, as desired. If the

latter is decided upon, allowance must be made on the length of the

rails for the tenons. The list given is for the dowel-made joints.

The following stock list gives the amount of material needed which

should be ordered planed and sanded. This work can be done by hand if

the builder has the time and desires to have an entire home-made

article. However, the list is given for the mill-planed material.

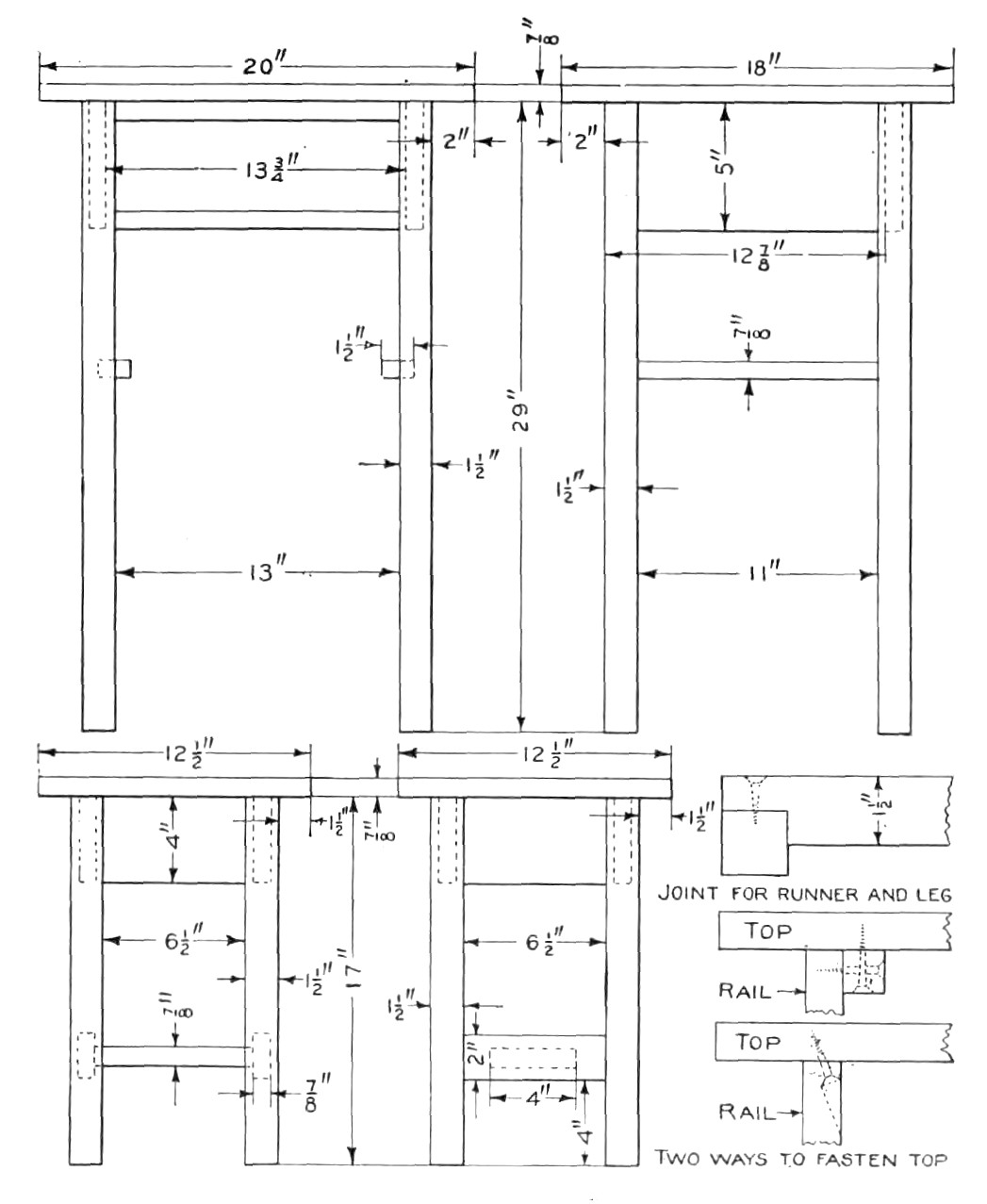

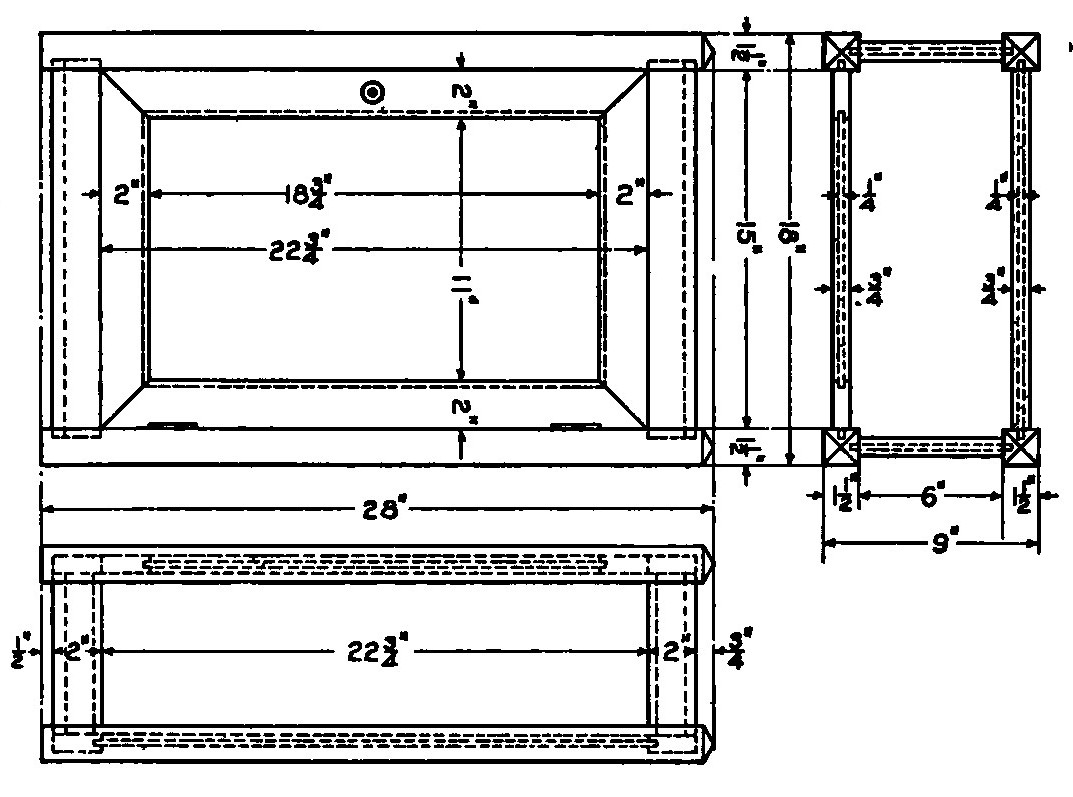

Details

of Stand and Stool

STAND

4 posts, 1 1/2 in.

square

by 29 in.

2 rails, 7/8 by 5

by 11

in.

1 rail, 7/8 by 1

1/2 by

13 in.

1 rail, 7/8 by 5 by

13

in.

2 runners, 7/8 by 1

1/2

by 14 in.

1 top, 7/8 by 18 by

20

in.

1 shelf, 7/8 by 12

7/8 by

13 3/4 in.

STOOL

4 posts, 1 1/2 in.

square

by 17 in.

4 rails, 7/8 by 4

by 6

1/2 in.

4 rails, 7/8 by 2

by 6

1/2 in.

1 stretcher, 7/8 by

4 by

7 1/4 in.

1 top, 7/8 by 12

1/2 in.

square.

The exact

lengths for the

posts are given in the list. Should the builder desire to square them

up, allowance must be made for this when ordering stock.

Arrange all the

pieces in

the position they are to occupy in the finished stand and stool and

number all the joints. Locate the centers and bore holes for all the

dowels. Assemble the two sides of the table first. Notch the runners

and fasten them to the posts with flat-head screws. Use hot glue on

the dowel joints if possible.

Cut the corners

out of

the shelf to fit the legs and assemble the frame of the table. Use

round-head screws through the rails to hold the shelf. The top may be

fastened in two ways, with screws through cleats on the inside of the

rails and under the top, or with screws slanting through the upper

part of the rails and into the top as shown. The stool is assembled

in the same manner as the stand.

The stand and

stool

should be finished to harmonize with the furniture and woodwork of

the room in which they are to be used.

(Click for larger image)

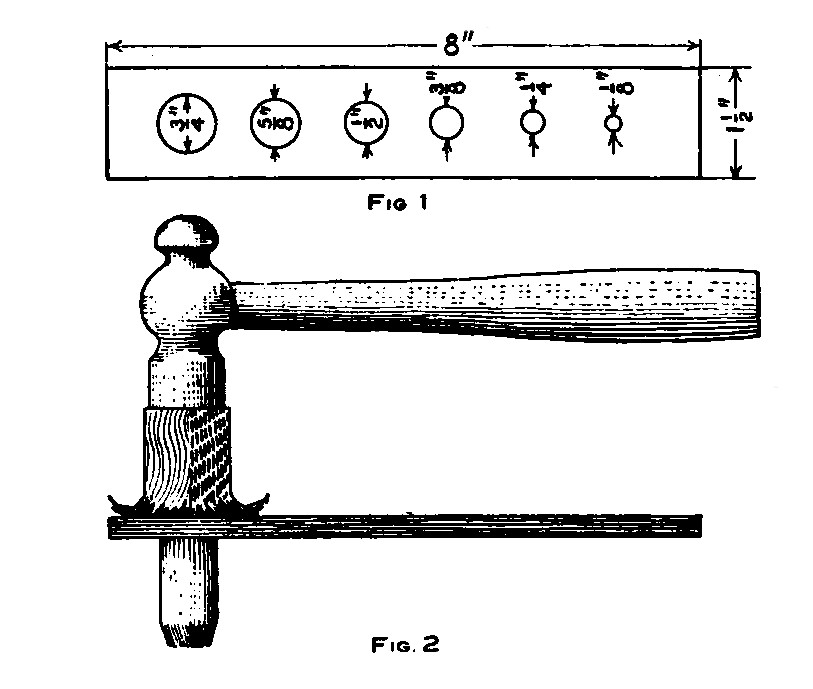

HOW

TO MAKE A DOWEL-CUTTING TOOL

Secure a piece

of steel

about 1/4 in. thick, 13/4 in. wide and 8 in. long. Drill various

sized holes through the steel as shown in Fig. 1, leaving the edge of

each hole as sharp as the drill will make them. Cut off a block of

wood the length necessary

for the dowels

and split

it up into pieces about the size for the particular dowel to be used.

Lay the steel on something flat, over a hole of some kind, then start

one of the pieces of wood in the proper size hole for the dowel and

drive it through with a hammer, as shown in Fig. 2. The sharp edges

on the steel will cut the dowel as smooth and round as if it were

turned in a lathe.

Easy

Way to Make Dowels

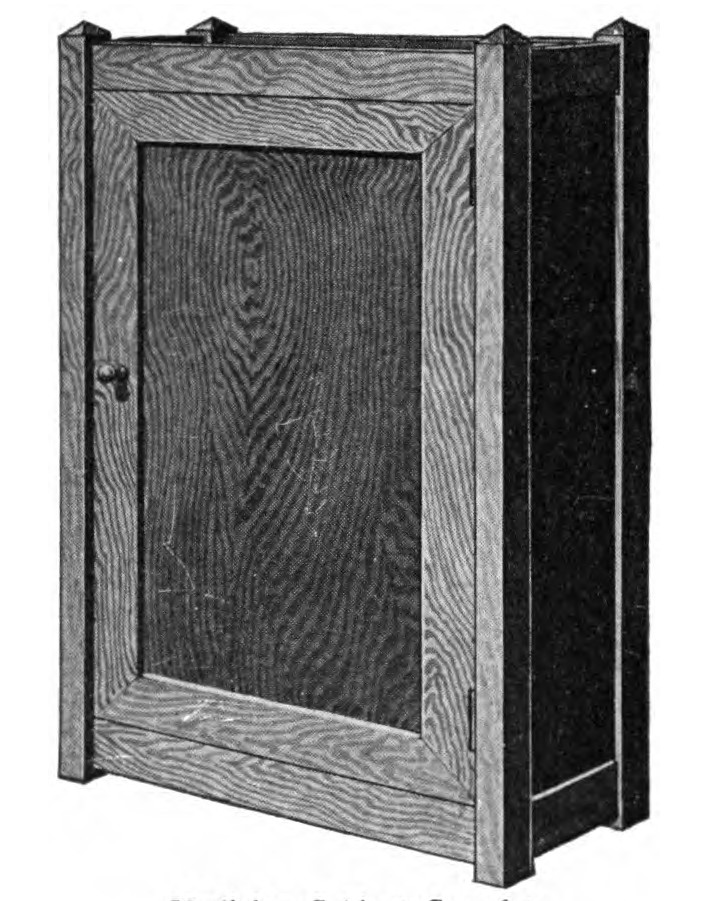

A MEDICINE CABINET

Medicine

Cabinet Complete

This cabinet is

best made

of quarter-sawed oak, as this wood is the most easily procured and

looks well when finished. Order the stock from the mill ready cut to

length, squared and sanded. The following pieces will be needed:

4 posts, 1 1/2 by 1 1/2

by 28 in.

4 side rails, 3/4

by 2 by

16 in.

4 end rails, 3/4 by

2 by

7 in.

2 door rails, 3/4

by 2 by

15 in.

2 door rails, 3/4

by 2 by

22 3/4 in.

1 door panel, 1/4

by 11

1/2 by 19 1/4 in.

1 bi.ck panel, 1/4

by 15

1/2 by 23 1/4 in.

2 end panels, 1/4

by 6

1/2 by 23 1/4 in.

2 pieces for top and

bottom, 1/2 by 6 3/4 by 15 3/4 in.

Square the four

posts and

bevel the tops as shown. Cut grooves in them with a plow plane to

receive the 1/4 in. panels. The tenons on the rails are cut 1/4 in.

wide and fit into the grooves in the posts the same as the panels.

The rails have grooves cut at the inside edges for the panels. The

front posts do not have grooves on the inside but have two mortises,

one at each end for the top and bottom rails. The back has a panel

fitted in the same as the ends. See that the pieces fit together

perfecly square and tight, then glue them together and give it time

to dry.

The top and

bottom boards

are next put in place. The top is placed in the center of the top

rails while the bottom is put even with the lower edge of the bottom

rails, as shown in the detail drawing. The door frame is mitered at

the corners and rabbeted on the inner edge to take the panel. A

mirror can be used in place of the panel if desired. Suitable hinges

and a catch, which can be purchased at a hardware store, should be

supplied for the door.

The shelves are

of soft

wood and are to be arranged to suit the maker. Before applying a

finish, go over the cabinet with fine sandpaper and remove all the

surplus glue about the joints and the rough spots, else the finish

will not take evenly. The finish can be any one of the many different

kinds supplied by the trade for this purpose.

(click for larger image)

|