A

BOOKCASE

This beautiful

piece of

mission furniture can be made at a very moderate cost by anyone who

has a slight knowledge of tool use much labor can be saved by

ordering the material prepared, i.e. mill ready cut to size, dressed

and sanded quarter-sawed oak is the best wood to use and it is

natively easy to obtain. Plain-sawed oak looks well, but is more

liable to warp than the quarter-sawed and this is quite an element in

pieces as wide as the ones used. For the complete bookcase the

following material will be needed:

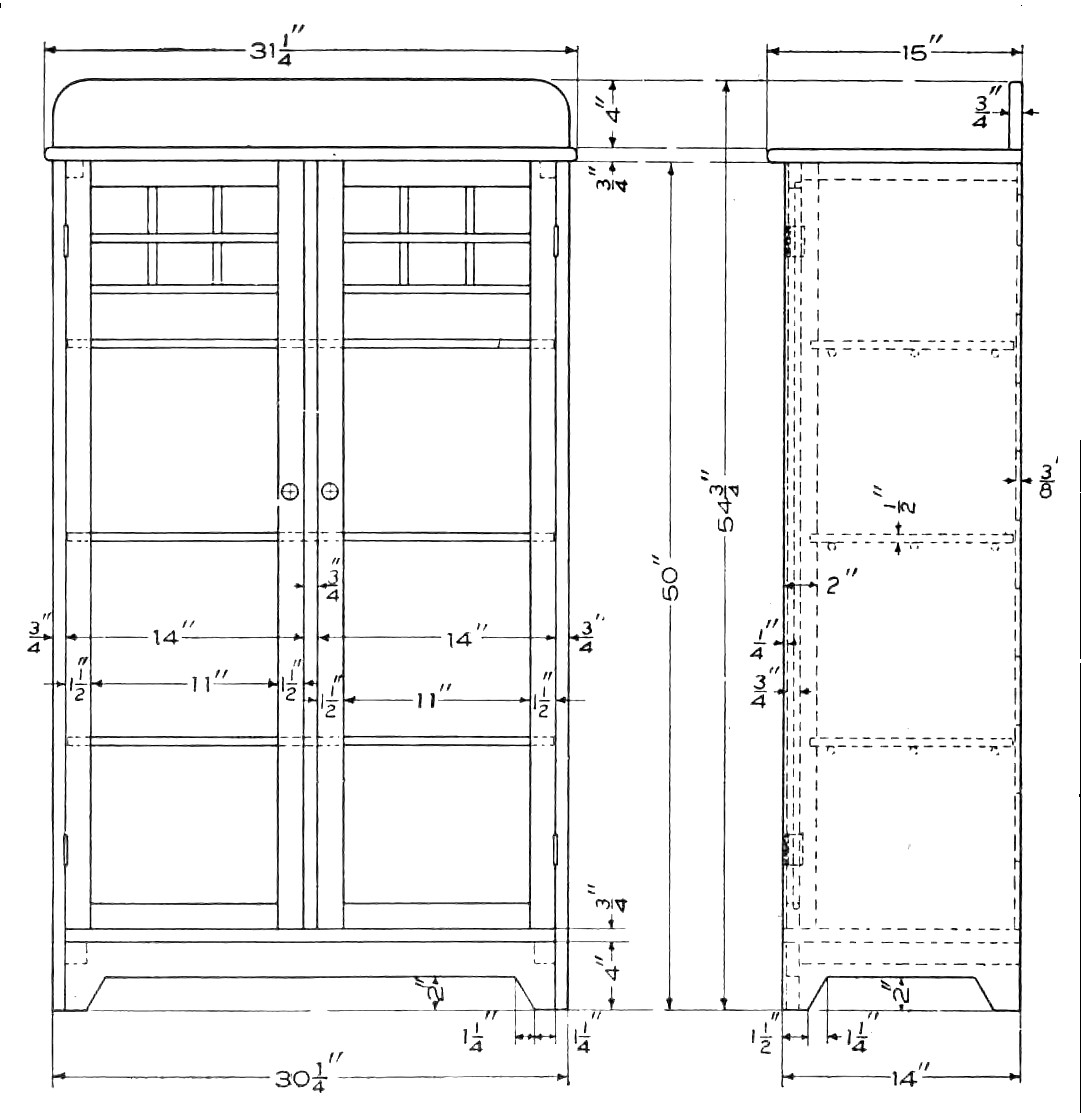

1 top, 3/4 by 15 by 31

1/4 in., hard wood, S-1-S.

1 top back board,

3/4 by 4 by 30

1/4 in., hard wood, S-1-S.

2 sides, 3/4 by 14

by 50

in., hard wood, S-1-S.

1 bottom, 3/4 by 14

by 28

3/4 in., hard wood, S-1-S.

1 bottom rail, 3/4

by 4

by 28 3/4 in., hard wood, S-1-S.

1 center piece,

3/4 by 2 by 45

3/4 in., hard wood, S-2-S.

4 door sides,

3/4 by 1 1/2 by

45 1/4 in., hard wood, S-2-S.

4 door ends, 3/4 by

PA by

14 in., hard wood, S-2-S.

4 pieces door

lattice,

1/2 by 1/2 by

12 1/2 in., hard wood.

4 pieces door

lattice,

1/2 by 1/2 by 7 in., hard wood.

2 bottom cleats, 1

1/4 by

1 1/4 by 13 in., soft wood.

2 top cleats, 1 by

1 by

12 1/2 in., soft wood.

3 shelves, 1/2 by

12 by

28 1/2 in., soft wood.

12 pieces backing,

3/8 by

4 by 29 3/4 in., soft wood.

4 hinges.

2 door handles.

Begin with the

sides by

cutting them so they will pair up all right. The front edges are

rounded while the back edges are rabbeted on the inside as deep as

the backing to be used. The bottoms are cut as shown in the sketch.

Holes about 1/2 in. deep should be bored on the inside at the proper

places for the wooden pegs which hold up the shelves.

The top and

bottom boards

should have the front edges rounded and sanded the same as the sides.

Completed

Bookcase

Details

of Bookcase

(click for larger image)

The top board is

sanded

on one side only and care should be taken to get the best side up.

Now cut and fit the top back board. This is fastened to the top by

means of screws. Screw two cleats to each of the sides as shown and

by running screws through these into the top and bottom boards the

frame is completed.

The backing

which can be

made of some cheap lumber is now put on. Next put in the center

upright piece between the doors by means of a tenon and mortise at

the top and nail at the bottom. The front edge should be rounded and

the edge and sides sanded. Cut and fit the bottom rail as shown. It

is fastened to the frame by means of cleats on the back side.

The doors are

put

together by means of a tenon and mortise. They should be rabbeted for

the lattice work and the glass. This lattice work can be omitted and

leaded glass put in its place which is very becoming to this kind of

work.

When the case is

completed it must be carefully gone over with sandpaper before any

finish is applied.

A mission stain

is

suitable for work of this kind, but it can also be finished in

"golden oak" which is done in the following manner: First

put on a golden oak stain and after it has dried for about 2 hours,

apply the filler. Let this dry about 10 minutes then rub off with an

old rag. Then go over the case again with some very fine sandpaper

and after seeing that all parts are free from dust and dirt the

varnish can be applied. Three coats of varnish will give a beautiful

glossy finish.

|