AN

ARM CHAIR

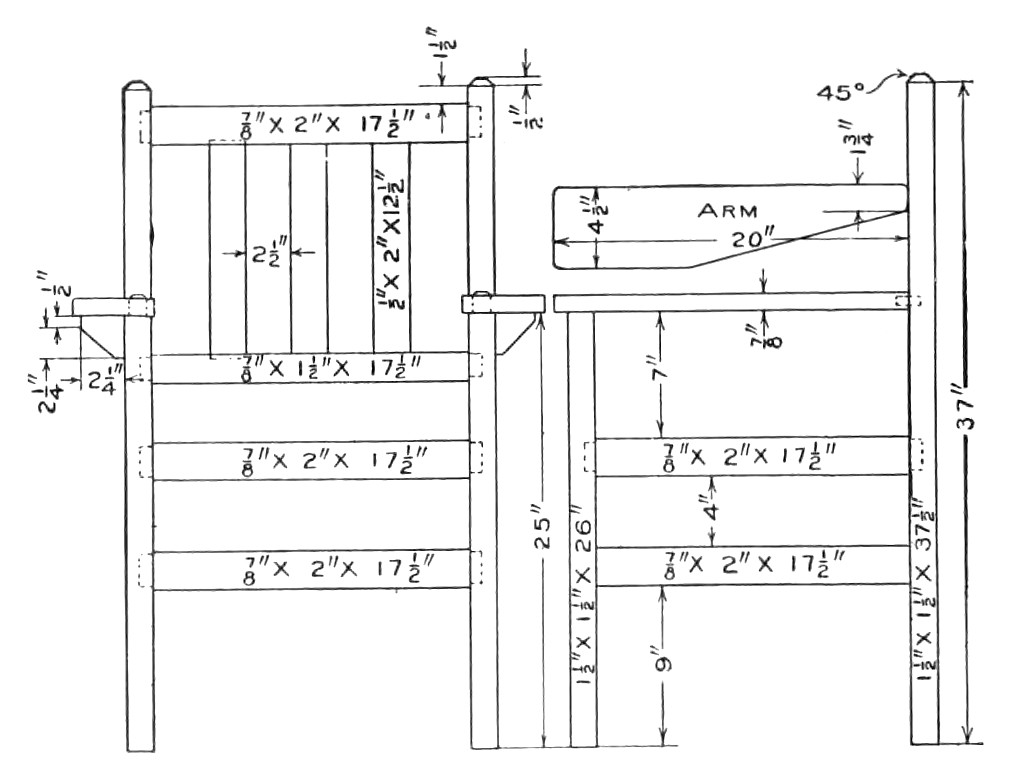

The arm chair

here

described and illustrated is intended to be one of the set of diners

made after the design of the side chair described on another page.

The same general directions for making the side chair apply equally

to the arm chair.

The stock given

in the

following list should be purchased surfaced on four sides and well

sandpapered:

2 rear posts, 1 1/2 by 1

1/2 by 38 in.

2 front posts, 1

1/2 by 1

1/2 by 26 1/2 in.

9 rails, 7/8 by 2

by 19

1/2 in.

1 rail, 7/8 by 1

1/2 by

19 1/2 in.

3 slats, 1/2 by 2

by 12

1/2 in.

2 arms, 7/8 by 4

1/2 by

20 1/2 in.

2 brackets, 7/8 by

2 1/4

by 2 1/2 in.

2 cleats, 3/8 by 1

by 19

in.

4 slats, 3/8 by 2

by 19

in.

Prepare the

posts first

by cutting them to the lengths shown in the drawing. In the

photograph the front posts have their tops cut off square and the

arms fastened to them by means of lag screws. A better way from a

mechanical point of view would be to shoulder the top ends on the

four sides, cut through-mortises in the arms and insert these tenoned

posts into these mortises, pinning the arm to the post by means of

small dowels in the edge of the post and through the tenon.

The brackets

under the

arms are to be fastened to the posts and arms by means of concealed

dowels and glue of good quality.

All of the rails

should

be tenoned into the posts thoroughly, even if the lag screw

fastenings are used. If the lag screws are used, the tenons may be

what are known as stubb tenons — tenons of short length. Good hot

glue should be used in either case.

Even the ends

with the

try-square and then carry the measurements just made across all of

them, using the try-square. The rails ought to be shouldered on all

four sides. Three-eighths inch is a good thickness for the tenons.

The width may be 1 1/4 in. and the length 1 in.

Place the rails

side by

side on the bench with the joint-edges up and the ends evened.

Measure off the desired length on one of them and carry the lines

across all of them to indicate the location of the shoulder lines.

Separate the pieces and square these lines entirely around all of the

sides of each piece. With the tenon saw rip and cross cut to these

lines.

The back, it

will be

noted, is set on a slant to add comfort. Thoroughly clean all the

parts and assemble them, .using good hot glue. Put the back together

first, then the front. After these have dried, put the side rails in

place.

Cut and fit the

two

cleats — one to the front rail and one to the rear rail. Keep them

even with the lower edge of the rail so as to form a slight recess at

the top when the slats are in place. This is to keep the cushion from

sliding off. The slats need not be "let into" the cleats

but merely fastened to their top edges. The cushion may be made of

Spanish roan skin and should be filled with elastic felt.

In the chair

shown, the

joints are reinforced by the addition of lag screws. If the glue is

good and the joints well fitted, these are not necessary.

Any unevenness

in the

lengths of the respective slats will not affect the fitting of the

joints by this latter method.

The tops of the

rear

posts in this chair, as in the side chair, are cut to angles of 45

deg., beginning the slope at lines marked 1/2 in. from the tops.

The bottom is

made up of

2 in. slats fitted between the front and back rails and fastened to

cleats which have been previously fastened to the insides of the

front and back rails. Keep these cleats low enough on the rails so

that the top surfaces of the slats shall rest somewhat below the top

edges of the rails. Cushions, such as the one shown, can be purchased

ready made or they can be easily made by the amateur.

A good finish

for this

chair and its mates is obtained as follows: Apply one coat of brown

Flemish water stain. This stain in the original package is very dark

in tone and unless an almost black finish is wanted, it should be

lightened by the addition of one-half or two-thirds water. Apply with

a brush or sponge and allow to dry over night. When dry, sandpaper

lightly with fine or worn sandpaper to remove the raised grain caused

by the water of the stain. Put on a very thin coat of shellac. This

is to prevent the "high lights" in close-grained woods from

being discolored by the stain in the filler which is to follow. The

shellac being very thin does not fill the pores of the wood

perceptibly. Next, sand the shellac coat lightly when it has

hardened. Apply a coat of paste filler colored considerably darker

than the stain to the tone desired for the open grain. If the filler

is well stirred and properly applied, one coat ought to be

sufficient. If it does not fill the pores satisfactorily, apply

another coat when the first has had time to harden. Vandyke brown is

used to color the filler, if none but natural color is to be had. On

the hardened filler apply a thin coat of shellac. On this apply

several coats of wax. The directions for waxing will be found upon

the cans in which the wax comes.

(Click for larger image) |